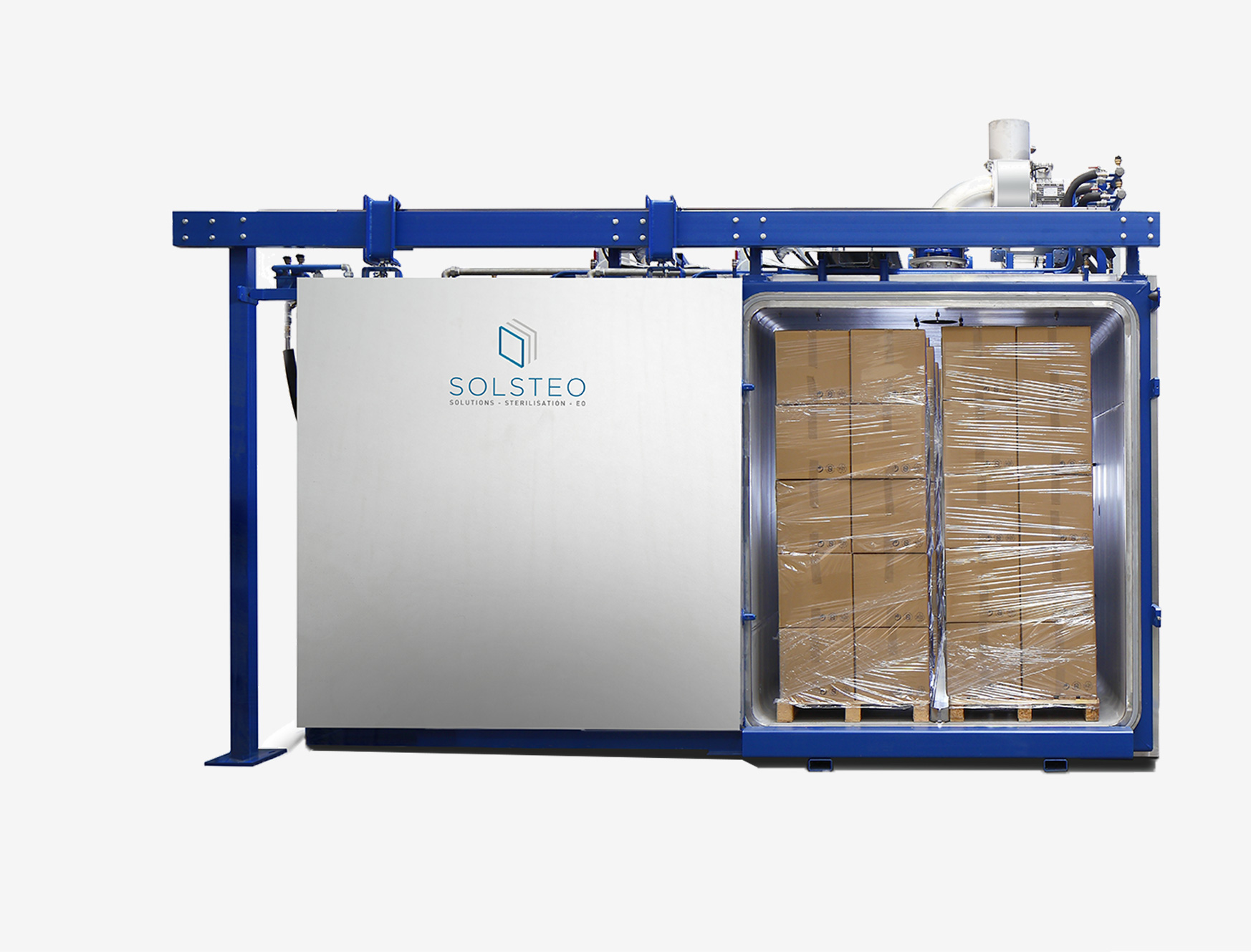

Thinking about integrating EO sterilization in-house?

15-YEAR MANUFACTURER’S GUARANTEE

We have been experts in this business since 2000. Our experience and in-depth knowledge of the EO sterilization process allow us to provide a 15-year manufacturer's warranty on SOLSTEO equipment.

Do you have questions about suitable methods

for EO gas disposal?

Find out more about SOLSTEO sterilization equipment